Research Aim

To

investigate the effects of asymmetric tooth profile and polymer mating gear on

the bending fatigue behavior and tooth deflection characteristics of

injection-molded polymer spur gears, and evaluate the influence of selective

laser sintering and build configuration on the bending fatigue behavior.

Methods

·

Fabrication of polymer

gears – Injection-molding (IM) and Selective laser sintering (SLS)

·

Evaluation of bending

fatigue life – Bending fatigue tests using in-house developed test rig

·

Study of thermal

behavior – Infrared thermography

·

Study of failure

morphology – Optical and Field-emission scanning electron microscopy

·

Evaluation of gear mesh

deflection – static deflection tests using in-house developed test setup

·

Prediction of stress

and deflection – Non-linear, viscoelastic, contact analysis in Abaqus/CAE

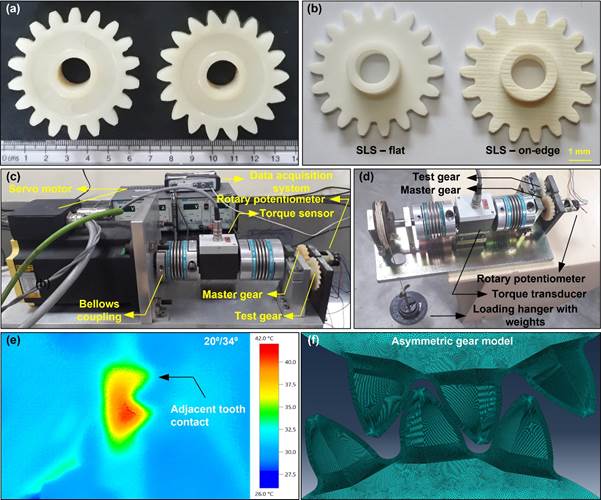

Figure 1. (a)

Injection-molded gears, (b) Selective laser sintered gears, (c) Bending fatigue

test rig, (d) Deflection test rig, (e) Sample infrared thermal image of

asymmetric gear (20°/34°), and (f) Finite element model of asymmetric gear (34°/20°).

Principal

findings

·

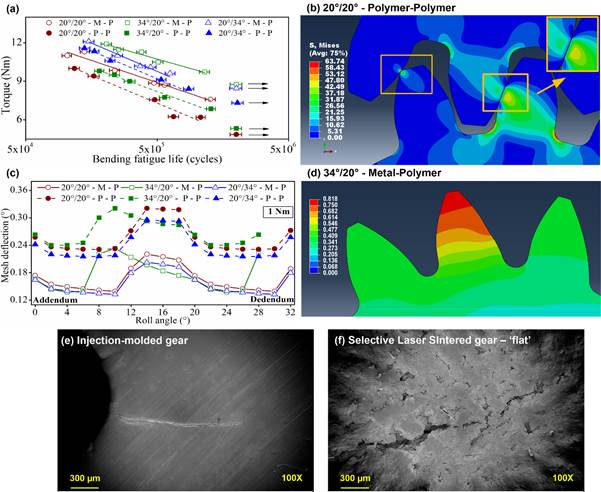

Asymmetric

configuration with greater drive side pressure angle causes maximum bending stress

reduction. Asymmetric configuration with lower drive side pressure angle

minimizes the hysteresis heat generation.

·

Bending fatigue

strength of metal-polymer pairs (M-P) of asymmetric gears depends on the

bending stress. In polymer-polymer pairs (P-P), operating temperature

determines the fatigue life.

·

Metal mating gear

enhances the mesh stiffness of the gear pair. Polymer mating gear balances the

mesh stiffness in the addendum and dedendum region.

·

Selective laser

sintered gears built in ‘flat’ configuration confers greater crack propagation

resistance. ‘On-edge’ build configuration varies the tooth layer orientation,

inducing significant anisotropy in bending fatigue strength.

Figure 2. (a)

Bending fatigue life of Injection-molded gears, (b) Typical von Mises stress

distribution in polymer-polymer pair of symmetric gear (inner: flat contact

surface owing to similar material stiffness), (c) Mesh deflection variation in

a cycle, (d) Tooth deflection variation in metal-polymer pair of asymmetric gear

(34°/20°), (e) Bending fatigue crack in injection-molded gear, and (f) Bending

fatigue crack in selective laser sintered gear built in ‘flat’ configuration.